Happy 2012, everyone!

Time to start real work on our automated PRT system. Since we’re a lean startup, here is the “Minimum Viable Product” that we’ll be focusing on during 2012 and 2013. It’s the smallest possible track that still tests all the necessary components and subsystems. The idea is to make a CAD model out of it this year.

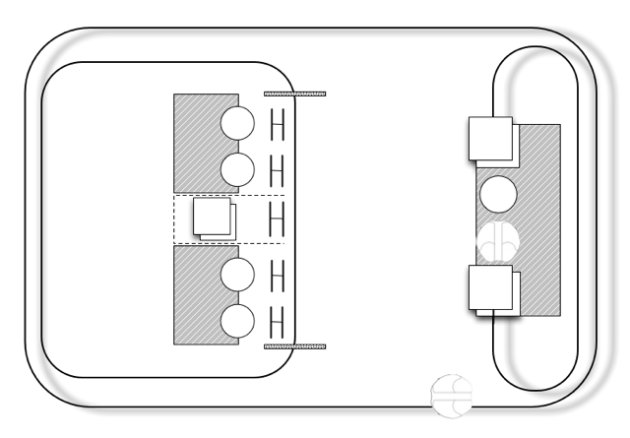

Let’s take you to a little ride in the proto track (and explain the picture – my graphic skills are not my stronghold):

To the right, there’s a light station (picture here), to the left a parallel station (picture here) and a vehicle stack (no picture). You will be able to travel between the two stations.

Light station

The light station fits 2-3 vehicles and is shared for both inbound and outbound traffic. It’s small in size and cheap in price. Pedestrians share the floor level with the vehicles; there are no safety doors. Within this shared space vehicles move extremely slowly and are observing their surroundings for obstacles (this is akin to how street-level automated vehicles move the whole way).

There are vehicle elevators both sides of the station. These take the outbound traffic up to track level and inbound traffic down to station. Electricity needed by the station is carried within the track itself; no connections to outside infrastructure is needed in the station.

The track loop behind the station works for both acceleration (outbound) and deceleration (inbound) traffic. This helps save space compared to having separate incoming and outgoing areas. Within such an area, the vehicles have track under both left and right sides. This helps in stabilizing the vehicle during “liftoff” and “landing”. Within “cruising” sections the vehicles would normally be supported only from left or right (this cannot sadly be presented in the drawing above easily; we’ll get graphics later which show this more clearly).

The track

It’s simply a big loop. That’s it.

The vehicle is supported by the right rail within the loop. You can see this from the positioning of the bottom-most vehicle currently, not from anything else.

Parallel station

This takes more space, and provides more capacity. In the picture, there are two inbound berths (vehicle slots) and two outbound ones. In between there is a vehicle “silo” – an automated storage facility that stacks empty vehicles out of the way and helps easily feed them into the outgoing station on demand peaks.

Traffic rolls on the outside loop anti-clockwise. There is a switching area for getting into or out of the parallel station. We’ll probably not do the acceleration/deceleration here, in order to affect the track traffic as little as possible. The switching happens in full speed. Only once out of the main loop, vehicles will slow down (the corners are too sharp for this currently; the track layout must be edited; but it’s good to test this real-world issue already here).

There are no vehicle elevators. Instead we’re sliding the vehicles down and letting them climb up on the track, on the outbound side of the station. This tests our climbing ability and may be needed for very high capacity stations anyways (though our elevators can take multiple vehicles at one time and essentially work as part of the track). Anyways, we’ll do slide and climb here.

Entering the station area, there are safety doors. This forms the borderline between automated and vehicle/human mixed mode areas. Again, we have no safety doors to keep passengers and vehicles apart.

The H-formed blocks are for the little carriage bars that move vehicles aside from the track and into their berths. First you have the incoming area, where people get off.

Then there is the vehicle stack, which is depicted with the same symbol as for the elevator in the light station. That’s because essentially it is an elevator. Only one that does not lead anywhere and which takes only empty, well charged vehicles.

Then there’s the outbound part, which is exactly like the incoming part of the station.

What’s missing?

A vehicle maintenance pit is not in the picture. We’ll need one but it’s essentially just a straight section of track. The most important part of the pit is the ability to change vehicle battery packs (similar to what Better Place or Rocla are doing with cars and forklifts). We’ll have to squeeze in a pitstop section to the layout.

Another missing piece is a lift for taking vehicles off the track and back on it. A simple portable crane with 1000kg capability will be enough (including the mass of passengers; the vehicles are intended to be around 350kg only). This is needed for emergency practice and simply to get vehicles off the track they are otherwise physically bound with.

Money

We don’t currently have any funding for this. We’ll make it anyhow.

Getting funding for the project is interesting, since on the one hand you have people who are saying “there’s one too few zeros behind the numbers” and on the other you have people wanting the budget to be smaller. This is because we’ve come to expect that things like this (“infrastructure”) are expensive. The challenge is to show, they need not be.

This is like making the Raspberry Pi of public transport (see that product, it’s an amazing credit-card size full-blown computer intended to boost a new generation of hackers).

2012

During this year, we’re making a CAD model of the above track. We’re also making a simulation software that allows for traffic control and capacity simulations.

If that goes well, and we get funding, we’ll make the actual track within some “garage” in 2013. Seems startups are back to garages. It feels good!